An intricate model fueled by cutting-edge technology is Olympia Entertainment’s secret weapon in developing the city

When Tom Wilson, president and CEO of Olympia Entertainment, was first trying to sell suites in Detroit’s soon-to-open Little Caesars Arena and leases in the surrounding buildings, it wasn’t always an easy deal. “We’re coming out of a tremendous period of upheaval in Detroit,” he says. “We’ve just come out of bankruptcy a few years ago; there wasn’t total confidence.” Wilson estimated it would take the better part of a year to sell out the stadium suites. Yet within 40 days of sales being open, his team had sold them all. Their unexpected aid? A 3D-printed model.

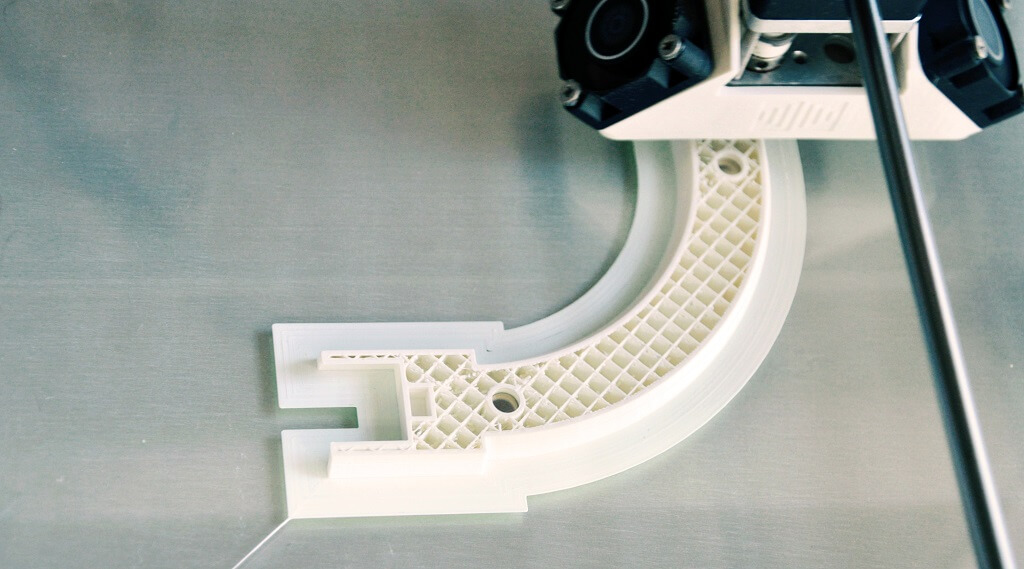

For its first time working with 3D modeling, Olympia had turned to Zoyes Creative Group, who used the state-of-the-art Stratasys Fortus 450mc 3D Printer to create a breathtakingly intricate model of the arena and the surrounding downtown district, all being developed by Olympia. Founder Dean Zoyes has been using 3D-printing technology since 2011, after years cutting his teeth hand-modeling buildings for architects and designers. Though Wilson may have been pleasantly surprised by the impact of the models, Zoyes wasn’t. “In terms of preconstruction marketing, there’s no better tool than a physical model,” he attests. “This type of additive modeling has really changed the industry overnight.” Chuckling, he adds, “My developers and architects try not to make that a true statement—they use all other models, be it visual or verbal, but when it comes down to it, there’s really nothing like being able to see for yourself a physical display model on a table, and especially one this intricate. The type of quality you get from a physical display, the value is inherent in that. There becomes this visceral attachment to a physical piece.”

The model in question was no standard project: Zoyes calls it “if not the biggest or the best we’ve ever done, the closest to it.” Stratasys project lead Jim Vurpillat explains, “Olympia wanted to, in a sense, bring this project to light because it was broader than just a new arena; there was a much bigger scope. They very quickly realized the only way to really bring this to life in the time they had was to use 3D-printing.”

The model in question was no standard project: Zoyes calls it “if not the biggest or the best we’ve ever done, the closest to it.” Stratasys project lead Jim Vurpillat explains, “Olympia wanted to, in a sense, bring this project to light because it was broader than just a new arena; there was a much bigger scope. They very quickly realized the only way to really bring this to life in the time they had was to use 3D-printing.”

The model features a nearly unparalleled standard of detail for 3D models. Each building, street, and signpost is rendered in exact scale, allowing both developers and potential purchasers to get a virtual sense of the space, which was, at sale time, little more than a giant construction lot. “Potential developers could see on a real scale what things are going to look like and how they’re going to work,” Wilson says. “It makes everything so much easier. They could see, ‘Oh, there will be a mass of people outside my building coming from the arena every night—that makes for good business.'”

Speaking of masses of people, what’s an arena without fans? Not much, according to Zoyes’s team, who made the last-minute decision to fill the model stadium with tiny fans. “We wanted to add some excitement to the inside of the bowl,” recalls Zoyes. “So I said, could we 3D-print fans with their hands in the air? So we did that, and our client thought it was just the coolest thing, so we ended up printing several groupings of people and then hand-placing them in rows. That probably took a good week. Someone’s job was to categorize the groups and put them in, all by hand.”

As development has continued, that model has become an evolving structure. “Once we had the stadium, the ballpark, the Fox Theatre, Fillmore, all built perfectly to scale with all of the features that you recognize, we could start painting the picture of what this arena is going to do and mean,” explains Watson. “And as they assembled it, the story became very real and became a great scene-setter for the next phase. We would look at something and say, ‘No, that’s a bit off, we’ll have to move that,” and kind of develop the project that way.”

As a result, the project is far from slowing down. “They will continue to use this,” says Wilson of his sales team. “We’ll continue to tell these stories for all the leases for the smaller buildings; that will be going on for probably the next five years. Every time you come in, there will be another little building, and it creates a sense of urgency.”

For Wilson, Zoyes, and Vurpillat, all Detroit natives, the project has become far more than a standard development. It’s part of a larger story about revitalizing their beloved city. Says Vurpillat, “I’m from Detroit for 28 years; it’s very exciting to see this growth happening in your hometown.”

Link to video showing progress on the 3D model project.

Buyers thought so, too: “Once everyone saw the arena, with the video and the whole presentation, almost everyone who bought a suite said part of the reason was that they really believed it would be a transformational change for the city,” Wilson recalls. “And they wanted to have a part of the city’s comeback.”

Adds Zoyes, “One of the things I don’t usually get to say is that I feel very lucky to be invited in on these projects. I’m the person that’s seen the inside of this arena before anyone else has. I can envision the spaces way faster with the advent of 3D printing, and we can help others visualize it as quickly as we do. It’s a real joy to be involved in Detroit. It’s on the move. Everyone calls it a revitalization, but it’s always been there. It’s just now coming to life.”